Vitrinor Advances in Energy Efficiency with the Renovation of the Stamping Area

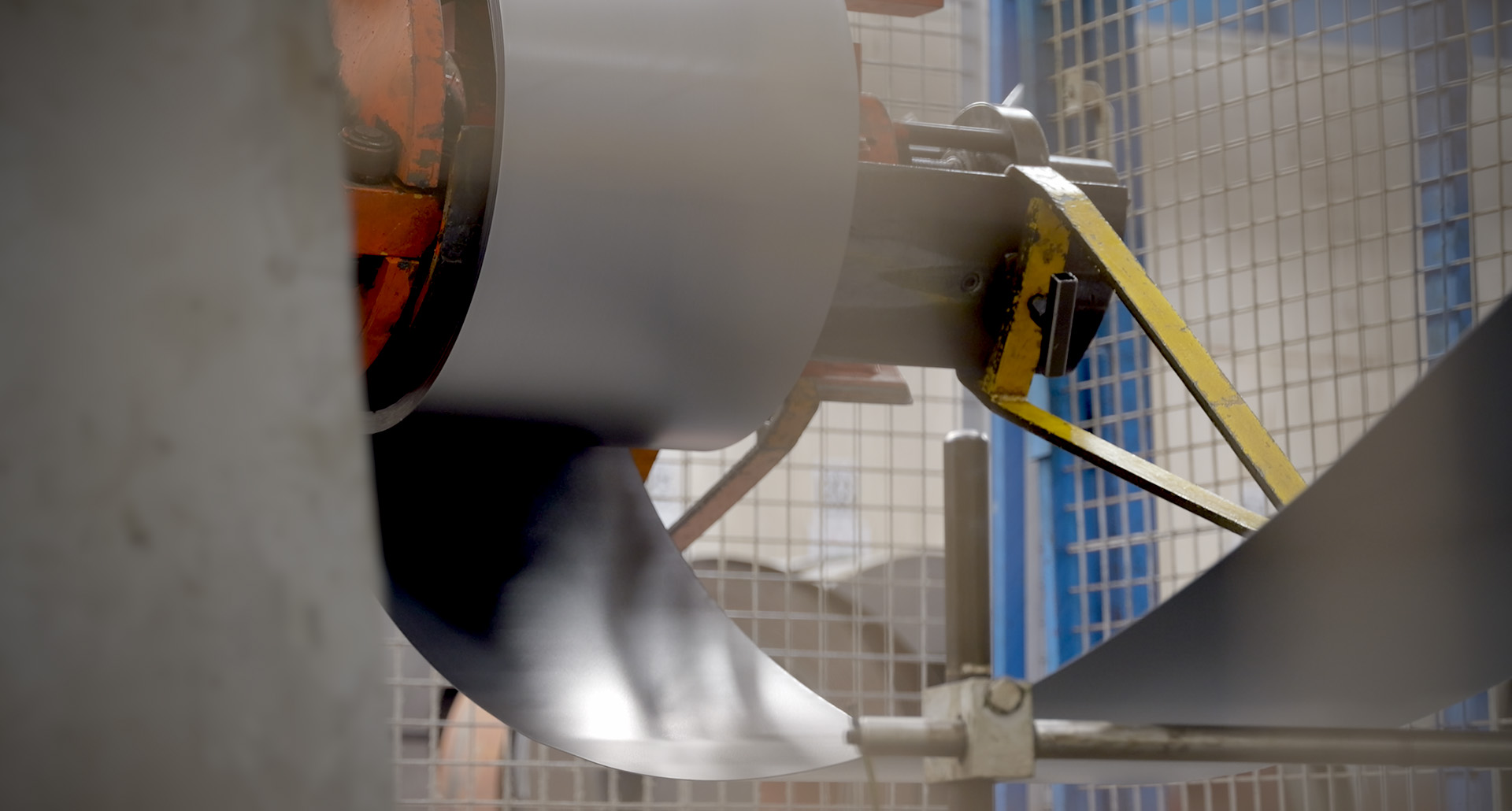

At Vitrinor, we continue to drive improvements that reinforce our commitment to more efficient and sustainable production. In this spirit, we have renewed the equipment in the stamping area, a fundamental process in the manufacturing of our cookware.

Stamping is the technique through which a sheet of steel is shaped under pressure to form the body of pans, pots, or casseroles. It is a key stage that ensures resistant, uniform, seamless pieces and directly impacts the final quality of the product.

This upgrade has been carried out within the SPIN2023 project, incorporating high-efficiency technologies that reduce energy consumption and optimise the performance of the process. With this improvement, we move towards a more responsible production model, maintaining the balance between innovation, quality, and sustainability that defines our daily work.